Sage 300 ERP | Manufacturing

An industrial strength manufacturing system that allows you the flexibility to choose just the functionality you need for your organization.

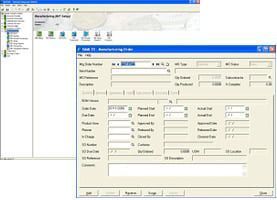

Manufacturing Order 5.4

Sage 300 Manufacturing?s Manufacturing Order is an easy-to-use manufacturing solution for small to medium-sized enterprises. Using Sage 300 ERP SDK, its design is fully integrated with Sage 300 ERP Finance and Logistics modules. Simple yet powerful, Sage 300 Manufacturing enables an efficient manufacturing operation flow covering material purchase, processing manufacturing orders, work in progress, routing cost calculation, material consumption, material scrap and item substitution and order closeout. The design of Sage 300 Manufacturing?s Manufacturing Order is conceptualized to fully accommodate users? business processes needs and expectations.

Multi-level Bill of Materials

- Supports multi-level Bill of Materials (BOM) structure.

- Unlimited number of BOM codes and revision numbers per item code.

- BOM based on standard formulation quantity for each product.

- Define scrap factors/production allowances for each component in the BOM.

- Archive Engineering Change Notice (ECN) information for each BOM structure.

- Use the different BOM status to manage items structure information.

Manufacturing Order Processing

- Plan, schedule, release and track manufacturing orders (MO) to better manage the production floor.

- Link MO with outstanding child or subcontract MO?s.

- Link MO with open sales orders (Sage 300 ERP OE) and purchase orders (Sage 300 ERP PO).

- Perform full and partial material issuances.

- Record production scrap and return of materials from the shop floor.

- Perform full and partial product receipts.

- Close out manufacturing orders (MO) and calculate actual costs and production variances.

Online Average Costing

- Cost of production is calculated at the point of posting.

- Material issuance cost is based on actual Sage 300 ERP IC inventory issuance cost.

- Finished good production cost is calculated as the sum of actual material issuance cost plus applied resource and tools cost divided by actual produced quantity.

- In order to accommodate partial manufacturing receipts, output is cost initially based on standard costs but is recomputed to actual upon MO closeout.

Operation-based Manufacturing

- Production floor is divided into work centers which are in turn accessed through production routing operations.

- Material components in a BOM is assigned to a distinct operation in the bill of manufacturing.

- Perform material issuances or returns by operation instead of just by MO.

- Perform production scrap by operation.

- Perform WIP allocation by operation.

- Perform material receipts by operation instead of just by MO.

Operation-based Standard Costing

- Production costs are classified as material costs, overhead costs, labor costs and tool costs.

- Material costs are further categorized as either direct or packaging.

- Material (direct and packaging) standard costs are derived from Sage 300 ERP IC standard costs.

- Overhead costs can be fixed or variable.

- Labor costs are composed of setup labor and direct or run-time labor costs.

- Resources and tools can be applied to work centers for costing purposes.

- Assembled standard costs derived from the BOM can be exported to Sage 300 ERP Standard Costs.

Work in Process (WIP) Monitoring

- Materials issued from Sage 300 ERP to an open Manufacturing Order (MO) is considered WIP.

- Manufacturing Orders may be grouped into Production areas/zones for purposes of tracking and management.

- WIP is consumed via the MO allocation transaction.

- MO closeout automatically allocates unconsumed WIP.

- Users have the option to keep track of WIP in the shop floor and generate current or historic WIP reports.

Component Substitution

- Provides for multiple component substitutes rated according to preference.

- Allows user triggered component substitution during MO Issuance based on inventory availability.

Tools Monitoring and Costing

- Tools are assets which are consumed during the manufacturing process.

- Consumption of tools may be fixed or variable.

- Tools can be categorized to user-defined tool types with pre-defined standard costs.

- The Tool Master allows the maintenance of actual tools with beginning quantities and actual costs.

- These tools are applied to MO?s and contribute to the actual product cost posted to Sage 300 ERP IC.

Reporting

- Item History Report

- Manufacturing Order (MO) History Report

- Manufacturing Order (MO) Status Report

- Production Variance Report

- Material Usage Report

- Production Output Report

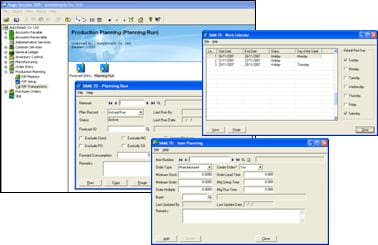

Production Planning 5.4

Sage 300 Manufacturing’s Production Planning module is an easy-to-use production scheduling and materials requirement planning solution for small to mediumsized enterprises. Developed using Sage 300 ERP SDK, it is fully integrated with Sage 300 ERP’s Financial and Logistics modules. The P/P module is the second installment of Sage 300 Manufacturing’s manufacturing suite for Sage 300 ERP. It makes full use of the manufacturing and BOM information in Sage 300 Manufacturing’s Manufacturing Order (M/F), sales information as contained in Sage 300 ERP O/E, stock data within Sage 300 ERP I/C and purchase information in Sage 300 ERP P/O. With Sage 300 Manufacturing’s P/P module, Sage 300 ERP can now truly generate a full blown basic MPS and MRP plan!

Flexible I/C Location Coverage

- User-defined P/P Distribution Networks determine the scope of individual MPS/MRP planning runs

- P/P Distribution Networks are composed of Sage 300 ERP I/C Locations

- Allows users to group or ungroup I/C Locations to form networks

- Supports unlimited number of P/P Distribution Networks.

Buyer/Planner Information

- Allows definition of unlimited number of buyers for purchased I/C materials

- Allows definition of unlimited number of planners for manufactured I/C products

- Create planned purchase orders by buyer and planned MO?s by planner

- Generate planning inquiries by buyer or planner

Item Planning Information

- Allows the user to define safety stock levels for each item record in I/C

- Allows definition of unlimited number of planners for manufactured I/C products

- Purchase and Manufacturing Lead Time can be maintained for each I/C item

- Option to automatically generate planned orders for selected items

Minimum Order (Lot)

- Generate realistic purchase or production plans with minimum order quantities per item

- Minimum order levels are useful to simulate purchase economic order quantities (EOQ) and supplier minimum order requirements

- Minimum order levels are also useful in simulating work center minimum batch or lot requirements

Consumption of Sales Forecasts

- Sales forecasts can be inputted or imported for use during planning runs

- Actual Sage 300 ERP O/E sales orders can consume user-defined sales forecasts thus preventing excessive estimation of item demand.

- Consumption tolerance can be defined by using backward and forward consumption days

Production Calendar

- Allows user-defined working and non-working days

- Sets the default working days for a normal week

Simplified Planning Runs

- User-friendly planning run interface requires only one click of a button to run the entire MPS and MRP planning process

Confirmed Planned Orders

- Generate purchase requisitions or manufacturing orders for planned orders

- Planned orders may be edited and converted to Confirmed Planned Orders

- Confirmed Planned Orders are treated as manual item allocations and are not automatically purged during planning runs

Time Buckets for Planning

- Allows an unlimited number of user-defined time buckets (e.g. Monthly, Weekly)

- Time buckets are applied to planning run results. No need to re-run planning module to switch from one time bucket to another.

Reporting & Inquiries

- MRP Summary Report

- MRP Summary Report – Costed

- Purchase Advice Report ? Summary

- Purchase Advice Report ? Detailed

- Production Advice Report ? Summary

- Production Advice Report ? Detailed

- Item Planning Inquiry

- Planning Action Report

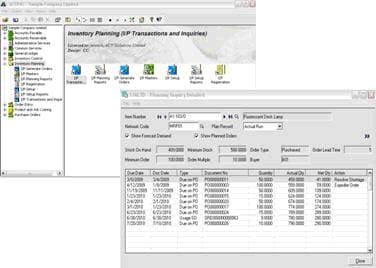

Inventory Planning 5.4

The Inventory Planning (I/P) module is an easy to use purchase planning solution for small to medium-sized trading enterprises. With I/P, trading companies can now generate full scale purchasing plans for all their inventory items.

Available to Promise (ATP)

- Allows salesmen to query and view online the available to promise quantity of selected items

- Provide stock inventory information such as on hand quantity, PO on order quantity, SO allocated quantity by location

- Displays the default sales price based on Sage 300 ERP I/C

- Displays summary customer credit status based on Sage 300 ERP A/R

- Includes a date-based sales history information

- Displays detailed item planning information for the selected item

Buyer Information

- Allows definition of unlimited number of buyers for purchased I/C materials

- Create planned purchase orders by buyer

- Generate planning inquiries by buyer

Item Planning Information

- Allows the user to define safety stock levels for each item record in I/C

- User may also define an order multiple (e.g. purchase unit) for each I/C item

- Purchase Lead Time can be maintained for each I/C item

- Option to automatically generate planned orders for selected items

Minimum Order

- Generate realistic purchase plans with minimum order quantities per item

- Minimum order levels are useful to simulate purchase economic order quantities (EOQ) and supplier minimum order requirements

Consumption of Sales Forecasts

- Sales forecasts can be inputted or imported for use during planning runs

- Actual Sage 300 ERP O/E sales orders can consume user-defined sales forecasts thus preventing excessive estimation of item demand.

- Consumption tolerance can be defined by using backward and forward consumption days

Flexible I/C Location Coverage

- User-defined I/P Distribution Networks determine the scope of purchase planning runs

- I/P Distribution Networks are used to group I/C Locations to form supply chains

- Supports unlimited number of I/P Distribution Networks

Planning Calendar

- Allows user-defined working and non-working days

- Sets the default working days for a normal week

Simplified Planning Runs

- User-friendly planning run interface requires only one click of a button to run the entire purchase planning process

- Includes option to exclude I/C stock, P/O orders, O/E orders

- Includes option to ignore minimum stock levels and work calendar

WhatIf? Scenarios

- Allows four (4) other planning records per Distribution Network to simulate WhatIf? scenarios

- Option to copy a source planning record to any target planning record

Auto Generation of Purchase Requisitions

- Planned orders can be automatically converted to P/O Requisitions via the I/P Generate PR routine

- Buyer has the option to combine or generate separate P/O Requisitions

- Buyer has the option to change order dates, due dates and order quantities for planned orders prior to generating P/O Requisitions

Reporting & Inquiries

- Purchase Planning Summary Report

- Purchase Planning Summary Report by Buyer

- Purchase Advice Report ? Detailed or Summary

- Purchase Advice Report ? Detailed

- Item Planning Inquiry ? Detailed or Summary

- Sales Forecast vs. Actual Sales Report

Related Links

Brochures

- Sage 300 ERP | Sage 300 Manufacturing Production Planning

- Sage 300 ERP | Sage 300 Manufacturing Manufacturing Order

- Sage 300 ERP | Sage 300 Manufacturing Inventory Planning